Mechatronic drive design: the increasing importance of energy efficiency

At the start of my career, I investigated energy

losses in mechatronic drives. We did a survey with several industrial

stakeholders on the importance of energy efficiency. Energy efficiency was

consistently rated less important compared to performance and durability. The

machine designer designed for infinite lifetime at the expense of higher energy

usage. While that finding made perfectly sense back then, with the current

changes in the world’s economy, energy efficiency starts to rightly gain

increased performance.

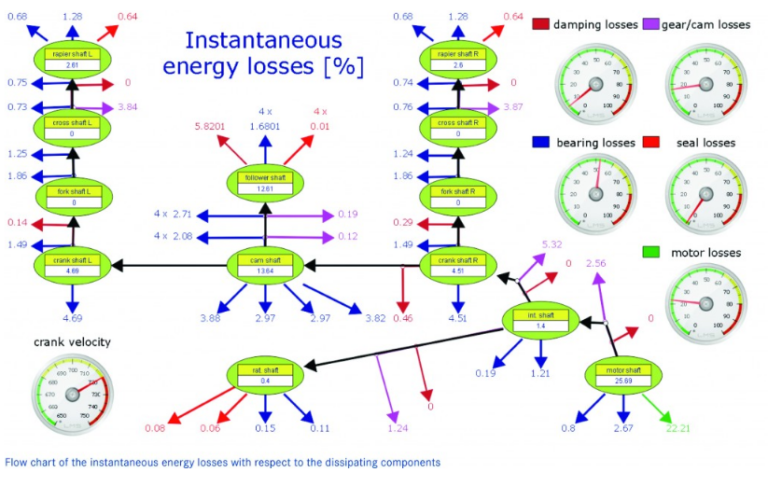

The most striking eye-opener in my research was

the strong interdependency between the different subsystems we modeled using

SIMCENTER Amesim. Energy does not simply flow from the actuator to the

end-effector but is stored and released in several flexible and inertial

elements throughout the drivetrain. Adapting small components changed power

flows and loading conditions on key components such as the bearing and gears.

Because loading conditions are the dominant mechanism for frictional losses,

energy consumption changed. Even more counter-intuitive was the fact that

adding damping on the right places can make machines more energy efficient!

With industry 4.0 and the emerging digital twin

concepts, I advocate to include energy efficiency to our modeling practices. And while we are

at it, I suggest using a Forcebit sensor to make of good assessment ;-).