Solutions

Improving energy efficiency

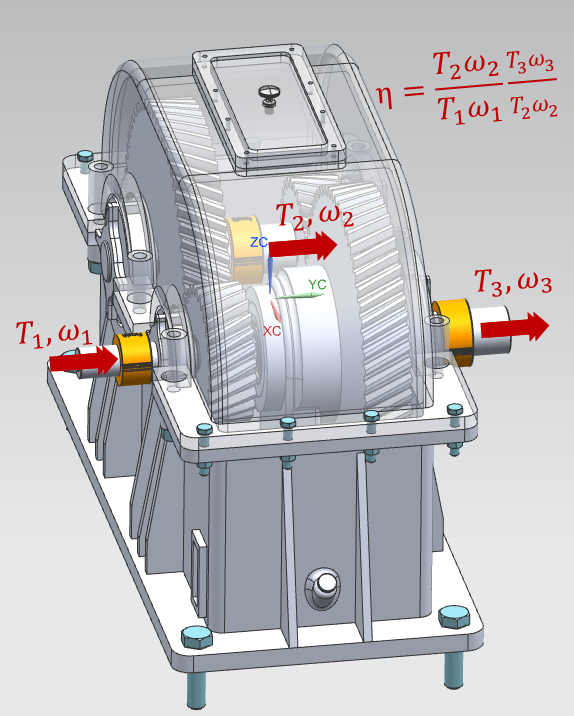

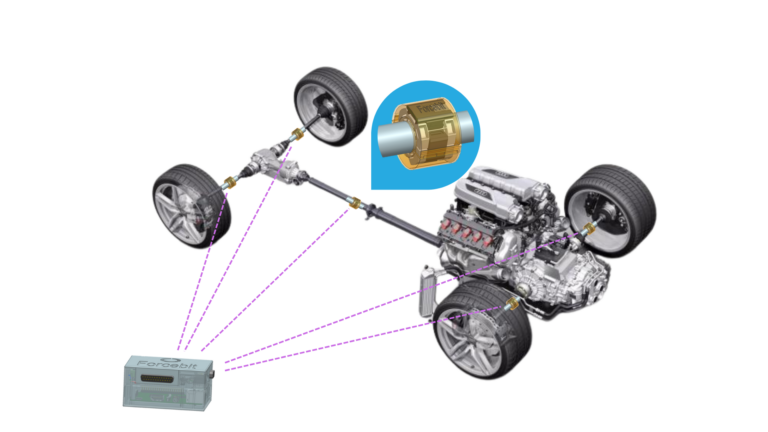

Whether it is a single gear stage or a full transmission, assessing energy losses of different parts of your drivetrain is always a challenge. Knowing the most important energy consumers in your design allows to better focus your efforts towards reducing the energy bill. Placing our forcebit sensor on various shafts within the drivetrain provides these insights.

Optimizing drivetrain design

What happens if I choose a smaller motor? What if I adapt my controller strategies? Experimentally assessing the consequences of these decisions requires meaningful and high quality measurements. Forcebit allows you to observe the impact of your decisions and assess the internal dynamics of your drive system. Torque, bending, angular displacement and accelerations are the bread and butter for mechatronic system designers to improve their machines.

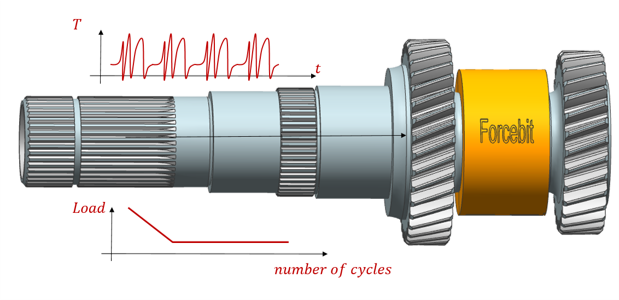

Estimate machine lifetime

Knowledge of both the instantaneous shaft loads (torque and bending) and velocity allows you to deduce the gear and bearing forces with their respective load cycles. This is key information for durability analysis and adequate sizing of the most critical components. Industry analysis has shown that companies are often in the dark when deciding on the size of their components. The resulting overdimensioning leads to inferior performance and increased costs. Using insights from our sensor, companies can ‘rightsize’ their machines.